One common issue our customers face when working with neoprene or SBR materials like stubby cooler panels is shrinkage. To help you avoid problems associated with this, we’ve developed a comprehensive plan that minimizes the shrinkage effect throughout the production process.

Here’s how we tackle shrinkage in stubby cooler panels and ensure high-quality products for our clients:

1. Resting Raw Materials for Stabilization

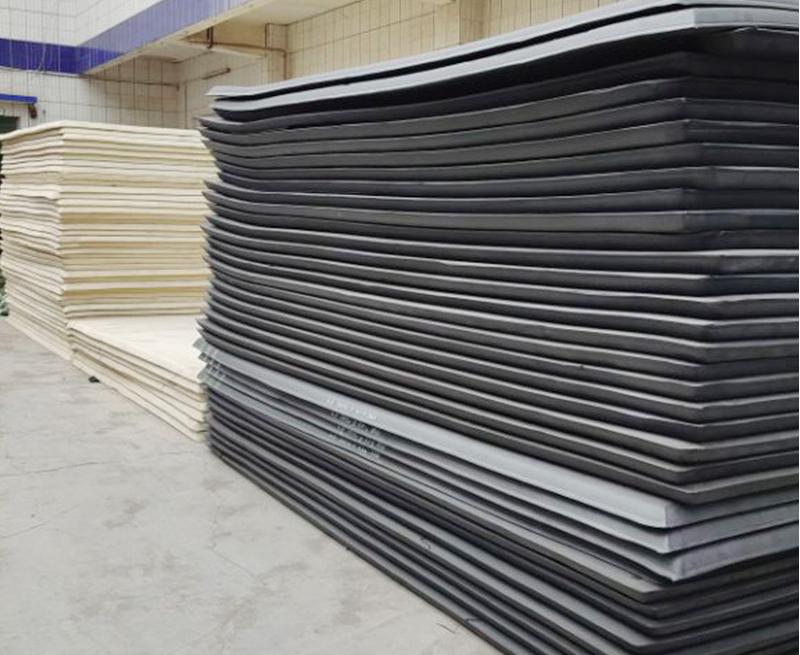

Once we receive the raw materials for production, we don’t rush straight into processing. Instead, we allow the materials to rest for a few days. This resting period gives the material time to stabilize, helping to reduce any shrinkage before we begin the production process. It’s an essential step in ensuring that the material doesn’t start shrinking unexpectedly during later stages of production.

2. Splitting the Material: Time to Rest Again

After splitting the material into the desired thickness of 7mm, we give it another period of rest. This ensures that the material’s shape and size remain stable before it’s laminated and cut into panels. The added time allows us to catch any early signs of shrinkage and make adjustments as needed.

3. Lamination Rest Period

Once the fabric is laminated to both sides of the material, we don’t proceed immediately to cutting. Instead, we allow another period of rest to ensure that the laminated layers bond properly and that any shrinkage that might occur after lamination is accounted for. By taking this extra time, we ensure the integrity of the product and avoid any future issues.

4. Final Resting After Cutting the Panels

Finally, after cutting the material into panels, we give it one last period of rest. This is the final chance for any natural shrinkage to occur before the panels are shipped out. By the time the panels are ready for delivery, we ensure that any shrinkage has already happened, reducing the chance of surprises when the product reaches your business.

Why These Steps Work

The extra resting time at each stage of production allows the material to shrink naturally and consistently. By giving each piece the time it needs at every step of the process, we can identify and remove any pieces that have shrunk excessively. This careful attention to detail ensures that the final product is as reliable and high-quality as possible.

However, increasing production time also increases costs. While this method can to some extent solve the problem, it also has drawbacks. When customers have tight deadlines, this approach is not suitable. Therefore, we can consider air freight and sea shipping to address this issue.

Shipping Considerations: Air Freight vs. Standard Shipping

We also recommend considering air freight shipping for your orders. When shipped via air, the shrinkage issue can be minimized because you can begin using the materials before they have a chance to shrink significantly. On the other hand, if materials are stored for a longer period before use, shrinkage is likely to stabilize before you start production, which also reduces the risk of problems.

Air freight has the advantage of speed, but if the order quantity is large, the transportation costs can be very high. Since stubby cooler panels are low-cost products, air freight is only suitable for urgent situations. So, how can we better solve the problem? Currently, the most suitable approach is:

Planning Ahead for Better Results

To further improve the production and delivery process, we suggest placing orders earlier. This gives us additional time to apply these extra steps in our production process and ensures that we have the necessary time to address any potential issues. Early orders help us provide you with the best possible products while maintaining flexibility in our production schedule.

At the same time, we are also exploring ways to improve the properties of neoprene material. Our goal is to prevent shrinkage without increasing costs or production time. We will update our blog with new methods as they become available.

Conclusion

We are committed to delivering high-quality neoprene material products, such as stubby cooler panels, bases, and unsewn can koozies, and that includes addressing any potential issues like shrinkage in materials. By implementing these careful production steps, we ensure that our stubby cooler panels—and all of our products—meet your expectations. If you have any questions or would like more information about our production process, don’t hesitate to reach out.

By following these strategies, we aim to provide our customers with reliable and high-quality products while effectively managing production challenges. Stay tuned to our blog for more updates and insights into our production processes and material innovations!